3.0 Squirt Water - Introduction

3.0 Squirt Water - Introduction Anonymous (not verified)The material in Chapter 3 describes aspects related to using water in wildland firefighting. These concepts include determining the weight of water, a description of factors related to friction loss, a review of basic drafting guidelines, as well as calculations related to volume, pump pressure, and flow rate. The chapter also provides instructions for estimating different parameters in the field, as well as a round-off table for ease of use.

3.1 Volume or Capacity

3.1 Volume or Capacity Anonymous (not verified)Volume is used to indicate the capacity of a tank or container. It is used by firefighters to answer questions like "How much water is left in the tank?" and "At 15 gallons per minute (gpm), how many more minutes before the tank is empty?"

VOLUME OF A RECTANGULAR OBJECT

The volume of a rectangular container is determined by multiplying the length (l) by the width (w) by the height (h).

Volume = length × width × height

V = l × w × h

Example 1 - Determine the volume of the tank in gallons.

Step 1. Use the equation for determining the volume of a rectangle. V = l × w × h

Step 2. Identify the length, width, and height. l = 5 ft, w = 6 ft, h = 8 ft

Step 3. Set up the problem and solve. V = 5ft × 6ft × 8ft = (5 × 6 × 8) (ft × ft × ft) = 240 ft3

Step 4. Determine the appropriate conversion factor. 1 cubic foot = 7.4805 gallons

Step 5. Set up the cancellation table so all units will cancel except gallons (see Section 2.1).

The volume of the tank of water is 240 cubic feet or 1,795 gallons.

Example 2 - The water tank on a newly designed engine is 34 inches wide, 5 feet high, and 12 feet long. What is the capacity of the water tank in cubic feet? In gallons?

Step 1. Use the equation for determining the volume of a rectangle. V = l × w × h

Step 2. Identify the length, width, and height. l = 12 ft, w = 34 in, h = 5 ft

Step 3. Convert all the measurements to the same units, feet.

Step 4. Set up the problem, and solve for volume. V = 2.83 ft × 5 ft × 12 ft = 170 ft3

Step 5. Set up the cancellation table so all units will cancel, except the desired unit, gallons.

The volume of the tank is 170 cubic feet or 1272 gallons.

VOLUME OF A CYLINDER

The volume of a cylinder is found by multiplying the area of the base times the height, h. The base of a cylinder is a circle, A = π × r2, where π = 3.14.

Example 3 - A cylindrical tank of foam concentrate is 5 feet tall. The tank diameter is 2.5 feet. What is the capacity, in gallons, of the tank?

Step 1. Use the equation for determining the volume of a cylinder.

V = π r2 × h

Step 2. Draw a sketch. Label the height and diameter.

π = 3.14, r = 1/2 d = 1/2 × 2.5 ft = 1.25 ft, h = 5 ft

Step 3. Set up the problem and solve. V = 3.14 × (1.25 ft)2 × 5 ft = 24.5 ft3

Step 4. Set up the cancellation table so all units will cancel, except the desired unit, gallons.

The tank capacity is 183.3 gallons.

3.2 Volume of Water in Hose

3.2 Volume of Water in Hose Anonymous (not verified)The volume of a hose allows an estimate of how much water can be delivered to the fire and is important in firefighting. The hose diameter is usually given in inches, with length in feet. The volume of a hose can be computed using the equation for volume of a cylinder in Section 3.1.

Example 1 - A 100-foot length of 1-inch diameter hose is charged with water. How many gallons of water are in that length of hose?

Step 1. Use the equation for determining the volume of a cylinder. V = π × r2 × h

Step 2. Identify the radius and height.

π = 3.14, r = 1/2 × d = 1/2 × 1 in = 0.5 in, h = 100 ft

Step 3. Convert all measurements to the same units. Convert the 100-foot hose length to inches.

Step 4. Set up the problem and solve. V = 3.14 × 0.5 in × 0.5 in × 1,200 in = 942 in3

Step 5. Set up the cancellation table so all units will cancel, except the desired unit, in this case gallons.

The capacity of a 100-foot length of 1-inch diameter hose is 4 gallons.

ESTIMATING IN THE FIELD

Rounding makes numbers easier to use. Sometimes estimations or approximations are useful, such as for problem-solving in the field, especially when without a calculator. For example, from Table 3.1 we see that 100 feet of 1-1/2 inch hose holds 9.2 gallons of fluid. In the field, the conversion value can be rounded to 9 gallons when doing rough estimations/calculations. These rounded values are easier to remember.

Example 2 - Sherman is out on a fire. His crew has a trunk line of 6 lengths of 100-foot, 1 & 1/2 inch hose. He needs to estimate the volume of water in this trunk line. What is a good estimate?

Step 1. Find the appropriate conversion/estimation in Table 3.1. Commit these rounded values to memory.

The exact tables indicate that a single 100-foot length of 1-1/2-inch hose holds 9.2 gallons of water (Table 3.1). Use the rounded value of 9 gallons per 100-foot length of 1-1/2-inch hose.

Step 2. Set up the table. This may or may not need to be done on paper. Typical rough estimations involve only one multiplication or division step, and usually this math can be done in your head.

Sherman has used 54 gallons of water to charge the hose lay.

Sherman now knows that he has about 54 gallons of water in his hose lay. The exact value would have been 6 × 9.2 = 55.2 gallons.

Rounded numbers are easier to use, because multiplying whole numbers is simpler than multiplying decimals. In example 6, the number was rounded down from 9.2 to 9.0. If it would have been rounded up from 9.2 to 10.0, the solution would have been 6 × 10 = 60 gallons. By performing the calculations using whole numbers, both higher and lower than the actual value, a margin is created. This margin allows for an upper and lower limit. It is therefore safe to say that the actual value is between 54 gallons (6 × 9) and 60 gallons (6 × 10).

DETERMINING WEIGHTS AND VOLUMES OF WATER

Table 3.1 shows the volumes of water in specific hose lengths, along with the weight of 1 gallon of water. The weight of 1 gallon of water is 8.3 pounds (1 gallon = 8.3 pounds). With this conversion, the weight of water can be calculated in a certain length of hose or volume of water by multiplying by 8 pounds per gallon (rounded value).

Example 3 - The tank on a Model 62 Engine is filled with 500 gallons of water. How much weight does the water add to the weight of the engine?

Step 1. Find the appropriate estimation in Table 3.1. 1 gallon = 8 pounds (lb)

Step 2. Set up the cancellation table so all units will cancel, except the desired unit, pounds.

The water in the tank adds 4,000 pounds to the weight of the engine.

Example 4 - Two 100-foot lengths of 1 & 1/2-inch cotton-synthetic hose weigh about 54 pounds total when dry.

How much will the same hose weigh when fully charged?

Step 1. Find the appropriate estimation in Table 3.1. The volume capacity of one 1 & 1/2-inch ID × 100-foot hose length = 9 gallons. For two lengths of hose, there are two times 9 gallons.

Step 2. Set up the cancellation table so all units will cancel, except the desired unit, pounds.

Step 3. Add the dry weight of the hose to the weight of the water. 54 lb + 144 lb = 198 lb

Two fully charged 1 & 1/2-inch ID × 100-foot hose lengths weigh 198 pounds.

Example 5 - An engine company is pumping a progressive hose lay with 1-inch laterals every 100 feet. At 800 feet up from the engine, the trunk line breaks. The firefighters replace it, but they forget to shut off the gated wye valve above the broken hose. As a result, they accidentally drain ten 100-foot lengths of 1-1/2-inch hose and ten 100-foot lengths of 1-inch hose. How much water above the break was lost due to this mistake?

Step 1. Find the appropriate estimation in Table 3.1 for the volume of water in both 1-inch and 1-1/2-inch lengths of hose.

Each 1-1/2-inch ID x 100-foot hose length holds 9 gallons.

Each 1-inch ID × 100-foot hose length holds 4 gallons.

Step 2. Set up the cancellation table so all units will cancel, except the desired unit, gallons, for each length of

hose.

Ten lengths of 1-1/2-inch ID x 100-foot hose

Ten lengths of 1-inch ID x 100-foot hose

Step 3. Add these together to find the amount of water lost. 90 gallons + 40 gallons = 130 gallons

The firefighters lost 130 gallons of water.

3.3 Friction Loss in Fire Hose

3.3 Friction Loss in Fire Hose Anonymous (not verified)Friction loss is the resulting resistance as water (fluid) moves along the inside wall of either a hose, pipe, or hose fittings.

Points to remember about friction loss:

- Friction loss increases as flow (gpm) increases.

- Total friction loss varies with length -- the greater the length, the higher the friction loss.

- Friction losses on reeled hose average about 21 percent more than for straight hose lays.

- Friction loss is nearly independent of pressure.

- Friction loss varies with type, lining, weave, quality, and age of the hose.

- Friction loss increases 4 times for each doubling of water flow. Reducing the diameter of a hose by 1/2 will increase the friction loss by a factor of 32 for the same flow.

To account for friction loss, the pressure at which the pump is working must be increased. The pump pressure must also be or decreased to compensate for the head loss or gain, to produce the desired nozzle pressure.

3.4 Calculating Engine Pump Pressures

3.4 Calculating Engine Pump Pressures Anonymous (not verified)To achieve a desired nozzle pressure (DNP), a few factors must be considered. First, you must note the head loss (HL) or head gain (HG). Water head is the height of the water column (lift) due to imposing pressure. The head pressure is positive (gain) if the hose lay is downhill because the force of gravity is helping push the water down, consequently increasing the pressure. The head pressure is negative (loss) if the hose lay is uphill, since the force of gravity is pulling the water down, when it needs to be pumped up. Table 3.1 indicates that 1 foot of water head or lift produces 0.5 pounds per square inch of pressure. On that same note, 1 pound per square inch can produce 2 feet of water head). For every foot uphill or downhill, there is a change of 0.5 pounds per square inch of pressure. Note that this measurement represents the height of the hose (elevation) and not the length of the hose.

Water Pressure vs Height. The drawings correspond to the pressure on a square inch cross section caused by the height of water above it. Note that as the column's height doubles, so does the pressure. Both exact and rounded field application values are given.

FRICTION LOSSES

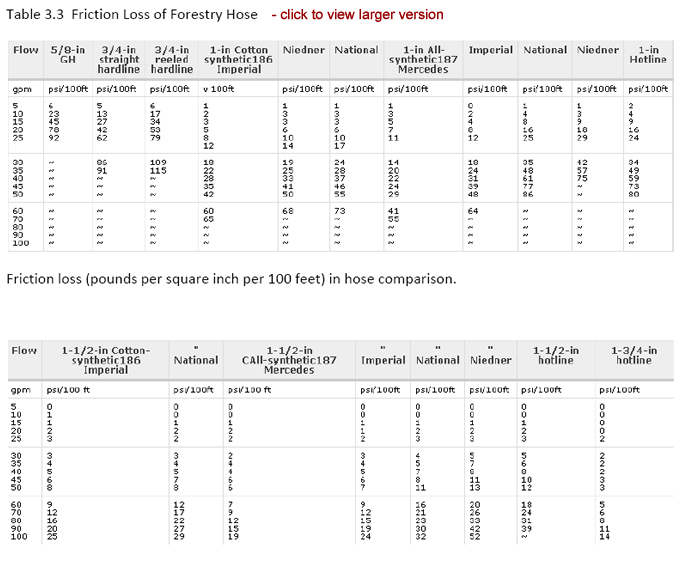

The second consideration for pump pressure calculations involves friction loss (FL). As a field rule, the pressure in a line is reduced by 5 pounds per square inch for each appliance added to the line. For example, a hose lay with five wye valves will result in a 25 pounds per square inch pressure loss due to the friction introduced by these fittings. This approximation is used to simplify calculations and is not precisely what occurs in the field. See Table 3.3 for friction loss in forestry hose.

CALCULATING DESIRED NOZZLE AND PUMP PRESSURES

Engine and nozzle pressures are calculated as follows:

DNP = Desired Nozzle Pressure

EP = Engine Pressure

HG = Head Gain

HL = Head Loss

FL = Friction Loss

Desired Nozzle Pressure equals:

Engine (Pump) Pressure ± (Head Gain or Head Loss) - Friction Loss

DNP = EP ± (HG or HL) - FL

When calculating desired nozzle pressure in a downhill hose lay, add the head pressure. In uphill hose lays, subtract the head pressure. The calculations vary to account for the work of gravity.

The head pressure is expressed in terms of loss or gain. Because the pump and the nozzle are at opposite ends of the hose, head pressure that is positive at the pump will be negative at the nozzle and vice versa. It is crucial that the sign of the head pressure be correct. If the hose lay is uphill, the head pressure is negative, and if it is downhill, the head pressure is positive. Careful attention must be paid to the sign of the head gain or head loss term, and whether the gain or loss should be added or subtracted.

Head gain and head loss depend on the nozzle's position relative to the pump.

ESTIMATING IN THE FIELD

As mentioned earlier, it is often necessary to round numbers either up or down to make calculations easier. When precise calculation is not possible because there is no paper, pen, or calculator, rounded estimations are helpful. In the field, rounding does not greatly affect the results. It can helpful to round numbers to take outside disturbances of any kind into account. For example, rounding the pressure caused by water head up from 0.434 to 0.5 takes into account any additional friction that might be caused by the hose itself.

For a 100-foot vertical height of water in the hose, using the exact value of 0.434 pounds per square inch per foot would give a 43 pounds per square inch (psi) head loss. This loss is 7 pounds per square inch less than what was calculated earlier. By rounding up to 0.5 from 0.434, friction and head losses due to the hose itself are taken into account, and no additional calculation is needed. In the field, the 0.5 pounds per square inch head loss is therefore used. This approximation not only eases calculations, but is more realistic to use in the field.

FRICTION DUE TO HOSE LENGTH

For hose lengths longer than 100 feet, friction loss in the hose should be considered. Friction loss of a 100-foot, 1-inch hose, all synthetic, with volume rate of 15 gallons per minute, is typically 4 to 9 pounds per square inch. Friction loss of a 100-foot, 1-inch hose, cotton-synthetic, at 15 gallons per minute, is typically 3 to 6 pounds per square inch. Friction loss for a 1.5-inch hose at 15 gallons per minute is typically 1 pound per square inch for 100 feet. See Table 3.3.

Example 1 - A progressive hose lay has six gated wye valves along the length of the trunk line. The nozzle outlet is 200 feet below the engine. The desired nozzle pressure of the trunk line is 100 pounds per square inch. At what pressure does the engine need to perform?

Step 1. Find the appropriate conversion/estimation in Table 3.1 for the pressure caused by 1 foot of water head. 1 ft = 0.5 psi

Step 2. Set up the cancellation table so all units will cancel, except the desired unit, psi. There is a head gain due to the hose lay being downhill.

Step 3. Set up the cancellation table so all units will cancel, except the desired unit, psi, to calculate the friction loss due to the fittings. Guidelines indicate a 5 pounds per square inch loss per fitting.

Step 4. Use the equation for the engine pressure. EP = DNP ± HG (or HL) +FL

Step 5. Identify the DNP, the HG, and the FL. DNP = 100 psi, HG = 100 psi, FL = 30 psi

Step 6. Set up the problem and solve. EP = 100 psi - 100 psi + 30 psi

The engine pressure needs to be 30 pounds per square inch for a desired nozzle pressure of 100 pounds per square inch in this hose lay.

STEP-BY-STEP PRACTICE

Kevin is fighting a fire and needs the nozzle pressure to be 100 pounds per square inch. He is 100 feet above the engine. What pump pressure does he need? Proceed through the questions below, which correspond to the steps necessary to solve the problem. After each step, click the next question button until you have reached the end of the exercise and have a value, in psi, for the engine pump pressure needed.

SIZE AND SHAPE VERSUS PRESSURE

The width or diameter of the tank does not affect the pressure. A column of water 100 feet high creates the same amount of pressure in a 2-foot diameter tank as it does in a 20-foot diameter tank. Think of people swimming in the ocean. They are not crushed by the pressure of such a large body of water because the pressure is the same if the height is the same, no matter how wide or what shape the container.

Different shaped tanks exhibit the same pressure.

WATER LEVELS

Knowing that 1 pound per square inch of pressure can lift water vertically 2 feet, the water level of certain volumes of water (a cistern or tank) can also be calculated.

Example 2 - An engine's compound gauge is connected at the base of a 100-foot tall reservoir tank, and the gauge reads 35 pounds per square inch. How high is the water level in the reservoir?

Step 1. Find the appropriate conversion/estimation in table 3.1 for the height of water that creates 1 pound per square inch of pressure. 1 psi = 2 ft of water head

Step 2. Set up the cancellation table so all units will cancel, except the desired unit, feet, to calculate the height of water that creates the 35 pounds per square inch of pressure above the gauge.

The water level is 70 feet above the gauge.

MORE PRACTICE

Harvey has parked his engine 30 feet below the base of a nearby water tank. He connects his engine's compound gauge to the water line coming from the tank and obtains a reading of 40 pounds per square inch. How high is the water level in the tank?

In this problem, the pressure is read not at the base of the tank, but at 30 feet below.

Hint. Find the appropriate conversion/estimation in Table 3.1 for the height of water that creates 1 pound per square inch of pressure. 1 psi = 2 feet

3.5 Drafting Guidelines

3.5 Drafting Guidelines Anonymous (not verified)It is important to know the difference in elevation between the pump and the water source when drafting water from a pond or stream. When drafting water, the air at atmospheric pressure is removed from the hose line, creating a vacuum (negative pressure) within the pump chamber. The atmospheric pressure (weight of air) on the water's surface forces the water up through the suction hose to the pump.

The maximum height to which an engine or pump can lift water is determined by the atmospheric pressure. At sea level, the atmosphere exerts an average pressure of 14.7 pounds per square inch (psi). Atmospheric pressure will vary due to changes in the weather. However, these changes tend to moderate themselves so that the average pressure will tend to go back toward 14.7 pounds per square inch. That is why it is safe to use this value of 14.7 pounds per square inch as a constant for calculations.

Example 1 - What would be the maximum height of water that a pressure of 14.7 pounds per square inch would be capable of sustaining?

Step 1. Find the appropriate conversion in Table 3.1.

1 psi = 2.304 ft

Step 2. Set up the cancellation table so all units will cancel, except the desired unit, feet, to calculate the lift created by 14.7 pounds per square inch.

The atmospheric pressure would be capable of sustaining a column of water 33.9 feet in height.

If a pump could produce a perfect vacuum, the maximum height to which it could lift water at sea level would be 33.9 feet, as shown in Example 1. This number is the maximum theoretical lift, but in practice no pump built can produce a perfect vacuum. A fire engine in fairly good condition can lift water two-thirds of the theoretical lift, 2/3 × 33.9 = 22.5 feet. This height is called the maximum attainable lift. With an increase in elevation above sea level, atmospheric pressure decreases, thus reducing the vertical distance from the water source where drafting can be done effectively.

ELEVATION EFFECTS

For every 1,000 feet of change in elevation, there is a loss of 1 foot in suction or lift and a 0.5 pounds per square inch decrease in atmospheric pressure.

Example 2 - An engine can lift water 22.5 feet at sea level. The same engine is driven to a fire at an elevation of 2,000 feet above sea level. What lift can the engine produce at this elevation?

Step 1. Use the conversion given for elevation change. A 1-foot loss = 1,000-foot elevation change

Step 2. Set up the cancellation table so all units will cancel, except the desired unit, feet, to calculate the loss in lift for a 2,000-foot elevation. (See Section 2.1 to review unit cancellations if desired.)

Step 3. Subtract the resulting value from the number of feet that can be lifted at sea level. 22.5 ft - 2 ft = 20.5 ft

This pump can lift 20.5 feet of water at a 2,000-foot elevation.

Example 3 - Larry is 16 feet above his water source, at an elevation of 4,000 feet. Will Larry still be able to draft water?

Step 1. Find the appropriate conversion/estimation in Table 3.1 to calculate the decrease in possible lift. At sea level, attainable lift is 22.5 feet.

Step 2. Set up the cancellation table so all units will cancel, except the desired unit, feet (loss), to calculate the loss in lift. Due to the elevation, the sustainable lift decreases by:

A 1,000-foot increase in elevation = 1-foot loss

Step 3. Calculate the adjusted attainable lift. The maximum attainable lift would now be: attainable lift - decrease due to elevation = adjusted attainable lift 22.5 ft - 4 ft = 18.5 ft

Step 4. Determine whether drafting is still possible. attainable lift = 18.5 ft so Larry would still be able to draft water up to a vertical distance of 18.5 feet. He desires to lift at least 16 ft.

18.5 feet - 16 feet = 2.5 feet above Larry's current location.

Yes, Larry is able to draft 16 feet above his water source.

3.6 Flow Rates

3.6 Flow Rates Anonymous (not verified)Flow rates describe the speed at which water is flowing. They are described in gallons per minute (gpm). The following test is a simple way to observe a flow rate.

Use a large drum with a marked level to indicate a pre-measured 50-gallon volume. Begin filling the drum with a hose and at the instant that the water begins to fill the tank, start timing how long it takes with a precise stop watch (preferably to 1/100 of a minute). When the water level reaches the marked line, take the hose away, and stop timing. To calculate the flow rate of the water through the hose, divide the total volume by the total time it took to reach that volume. Suppose it took 3.55 minutes.

50 gallons per 3.55 minutes (50/3.55)

50 ÷ 3.55 = 14.08

Flow rate = 14.08 gpm

If the stop watch has only seconds and minutes, the seconds can be converted into fractions (parts) of minutes. There are 60 seconds in 1 minute.

Table 3.1 Water Handling Unit Estimations

Table 3.1 Water Handling Unit Estimations Anonymous (not verified)| Description ID = Inner Diameter |

Rounded Values Used in U.S. Measure Field Estimations GOOD TO MEMORIZE ID = Inner Diameter Volume (Capacity) |

U.S. Measure Volume (Capacity) |

|---|---|---|

| One hose length | ||

| 1-1/2-in ID x 100 ft | 9 gal | 9.2 gal |

| 1-in ID x 100 ft | 4 gal | 4.1 gal |

| 3/4-in ID x 50 ft | 1 gal | 1.2 gal |

| 5/8-in ID x 50 ft | 1 gal | 0.8 gal |

| Weight | Weight | |

| 1 gal of water at 20°C | 8 lb | 8.3 lb |

| Pressure | Pressure | |

| 1 ft of water head (1 in2 column of water) | 0.5 psi | 0.434 psi |

| Atmospheric pressure | 15 psi @ sea level | 14.7 psi @ sea level |

| 1,000 ft increase in elevation | 0.5 psi decrease in atmospheric pressure | 0.5 psi decrease in atmospheric pressure |

| Draft (lift) | Draft (lift) | |

| 1 in of mercury | 1 ft | 1.134 ft |

| 1,000 ft increase in elevation | 1 ft loss | 1 ft loss |

| Maximum theoretical lift | 34 ft | 33.9 ft |

| Maximum attainable lift with new pump | 29 ft * | 29.4 ft |

| Maximum practical attainable lift | 22 ft | 22.4 ft |

* Pump lift varies with pump efficiency, which decreases proportionately to the hours of use.

Table 3.2 Comparative Diameters and Weights (100-foot lengths) of Coupled Fire Hose

Table 3.2 Comparative Diameters and Weights (100-foot lengths) of Coupled Fire Hose Anonymous (not verified)| Type of Hose | FS SPEC | Jacket | ID (in) | Factory Proof Pressure (psi) | Burst Pressure (psi) | Max Dry Weight (lb) | Water (gal) | Weight Water (lb) | Max Total Weight (lb) |

|---|---|---|---|---|---|---|---|---|---|

| Garden synthetic jacket, lined (50 ft only) | Item purchase description | Single | 5/8 | 300 | 550 | 1.7 | 0.8 | 6.6 | 8.4 |

| High pressure, reel (50 ft only) | 5100-185 | 3/4 | 1,200 | 2400 | 28.4 | 1.2 | 10 | 38.4 | |

| Cotton-synthetic jacket, lined | 5100-186 | Single | 1 | 450 | 900 | 22.4 | 4.1 | 34 | 56.4 |

| Synthetic jacket, lined | 5100-187 | Single | 1 | 450 | 900 | 9.4 | 4.1 | 34 | 43.4 |

| Cotton-synthetic jacket, lined | 5100-186 | Single | 1-1/2 | 450 | 900 | 26.9 | 9.2 | 77 | 103.9 |

| Synthetic jacket, lined | 5100-187 | Single | 1-1/2 | 450 | 900 | 15.9 | 9.2 | 77 | 92.9 |

| Cotton-synthetic jacket, rubber lined (light tube) (50ft only) | None | Single | 1-1/2 | 60 to 162 | 25.5 | 213 | 273 to 375 |

Table 3.3 Friction Loss of Forestry Hose

Table 3.3 Friction Loss of Forestry Hose Anonymous (not verified)Friction loss comparison of the forestry hose and hose on the Forest Service qualified products lists for 5100-186 and 5100-187 in units of pounds per square inch per 100 feet.